Chemical imaging & tomography

Finden works directly with clients on short commissioned projects, but is also involved in long term research projects with clients and partners from across the world. Examples are given below including a case study.

Further case studies include:

Arriving at five dimensional diffraction imaging

Arriving at five dimensional diffraction imaging

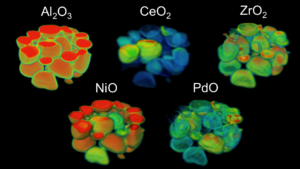

We report the results from the first 5D tomographic diffraction imaging experiment of a complex Ni–Pd/CeO2–ZrO2/Al2O3 catalyst used for methane reforming.

Developing the next generation data collection strategies for x-ray chemical imaging

Developing the next generation data collection strategies for x-ray chemical imaging

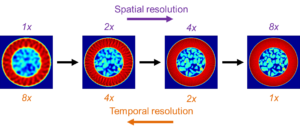

An X-ray diffraction computed tomography data-collection strategy that allows, post experiment, a choice between temporal and spatial resolution is reported.

Towards artefact free-x-ray diffraction tomography images

Towards artefact free-x-ray diffraction tomography images

This paper reports a simple but effective filtering approach to deal with single‐crystal artefacts in X‐ray diffraction computed tomography (XRD‐CT).

Enabling X-ray diffraction computed tomography (XRD-CT) for large samples

Enabling X-ray diffraction computed tomography (XRD-CT) for large samples

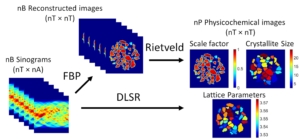

Over the past decade XRD-CT has gained a lot of attraction as a materials characterisation technique that allows for spatially resolving the chemistry inside samples in a non-destructive manner. However, one of the limitations of the technique is related to the sample size due to the parallax artefact. The parallax artefact arises from relatively large samples where X-rays, scattered from a scattering angle 2θ, arrive at multiple detector elements. This phenomenon leads to loss of physico-chemical information associated with diffraction peak shape and position (i.e. altering the calculated crystallite size and lattice parameter values, respectively) and is currently the major barrier to investigating samples and devices at the centimetre level (scale-up problem). We have developed a new tomographic reconstruction algorithm, termed Direct Least-Squares Reconstruction (DLSR) algorithm, which solves the parallax artefact problem in XRD-CT.

Read more about our team and publications.