Case Study: Ultra-fast full profile analysis of powder diffraction data using the PQ-Net deep convolutional neural network

Companies involved:

Finden Ltd, University College London, NPL, STFC’s SciML, VITO

Challenge:

Over the past decade, advancements in X-ray sources, optics and detector technologies have led to a dramatic increase in the volume and data quality of experimental powder diffraction patterns. These technical advances are beginning to make high-throughput powder diffraction measurements a reality not just at synchrotron facilities but also at the laboratory. It is currently well-accepted that it is the data analysis that is emerging as the bottleneck for measurement science and not the data acquisition and/or the experiment itself. Conventional data analysis methods, such as least-squares minimisation approaches, are not able to keep up with the data collections rates and there is a need for alternative methods which can provide both fast and accurate results.

Sample:

Ni-Pd/CeO2-ZrO2/Al2O3 fixed bed reactor

Solution:

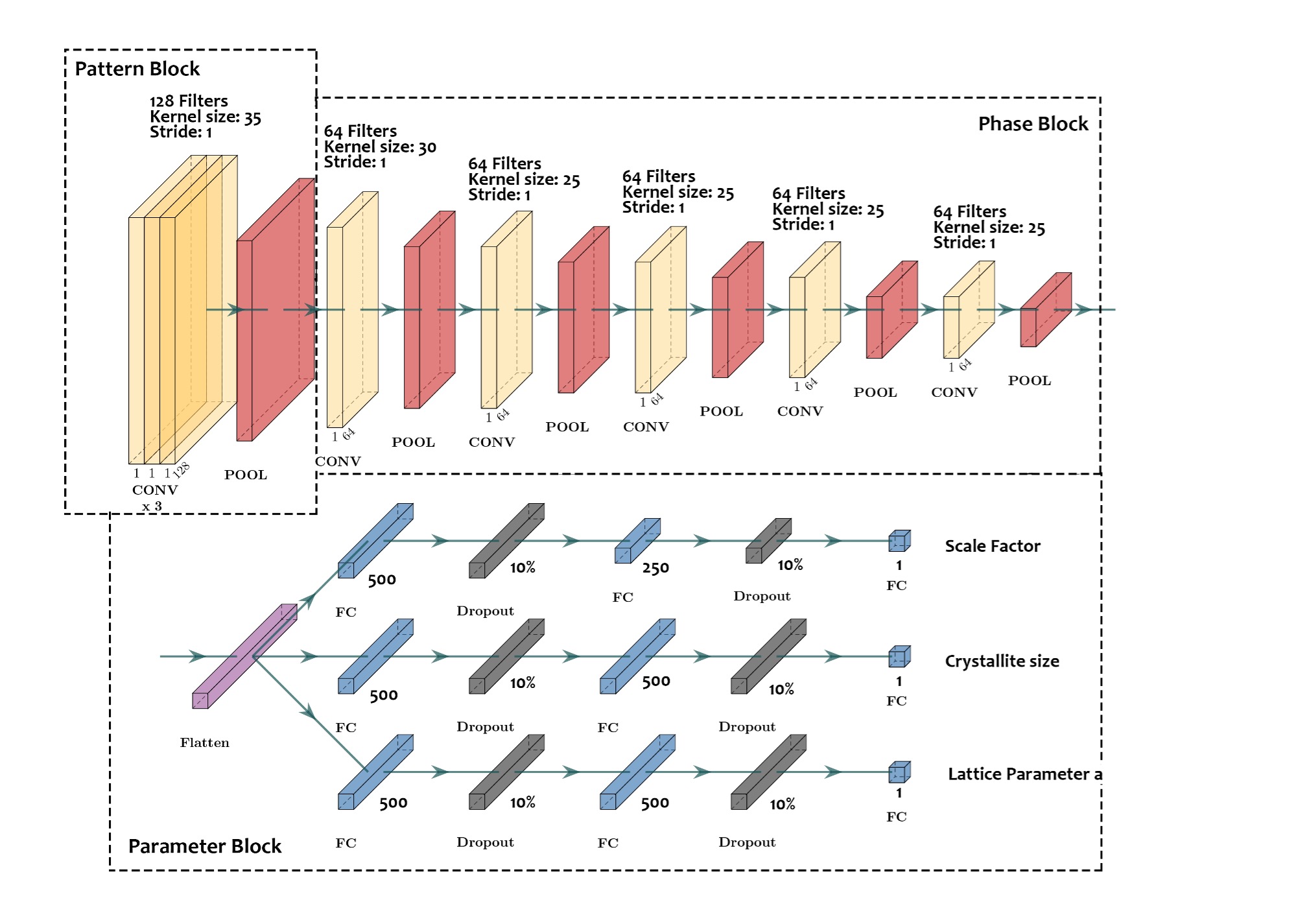

We have developed the Parameter Quantification Network (PQ-Net), a regression deep convolutional neural network providing quantitative analysis of powder X-ray diffraction patterns from multi-phase systems. The network is tested against simulated and experimental datasets of increasing complexity with the last one being an X-ray diffraction computed tomography dataset of a multi-phase Ni-Pd/CeO2-ZrO2/Al2O3 catalytic material system consisting of ca. 20,000 diffraction patterns. It is shown that the network predicts accurate scale factor, lattice parameter and crystallite size maps for all phases, which are comparable to those obtained through full profile analysis using the Rietveld method, also providing a reliable uncertainty measure on the results. The main advantage of PQ-Net is its ability to yield these results orders of magnitude faster showing its potential as a tool for real-time diffraction data analysis during in situ/operando experiments.

Benefits:

The key advantage of the PQ-Net is that the diffraction libraries can be generated prior to an experiment and used to pretrain the model. This approach can allow for real-time assessment of diffraction data acquired during a dynamic experiment and enable the user to better guide the experiment (e.g., through the applied operating conditions) and intervene when necessary. In future, we plan to increase the complexity of the PQ-Net and explore its ability to model other parameters such as complex backgrounds, to quantify amorphous/crystalline components and to perform simultaneous calculation of weight percentages and strain analysis. It should be pointed out that the PQ-Net could in principle also be used to benefit X-ray Free Electron Laser (XFELs) facilities, like the European XFEL (Germany), for fast analysis of powder diffraction data. We will also try to apply the PQ-Net on other analytical scattering/spectroscopic techniques such as X-ray absorption fine structure spectroscopy (XAFS) data which is a technique suitable for large volume data analysis (e.g., XAFS-CT). Last but not least, we expect that the PQ-Net has the potential to become an essential tool for diffraction applications beyond synchrotron experiments such as real-time quality inspection in manufacturing/synthesis.

Further reading:

A deep convolutional neural network for real-time full profile analysis of big powder diffraction data. Dong H., Butler K.T., Matras D., Price S.W.T., Odarchenko Y., Khatry R., Thompson A., Middelkoop V., Jacques S.D.M., Beale A.M., Vamvakeros A., npj Computational Materials, 7 (74), 2021, DOI: https://doi.org/10.1038/s41524-021-00542-4