Case Study: Unveiling Early-Cycle Chemical Heterogeneities in a Commercial 18650 NCA Li-ion Battery through Synchrotron X-ray Diffraction Tomography (XRD-CT)

Companies involved:

Finden Ltd, ESRF, The Faraday Institution, Diamond Light Source, University College London

Challenge:

Li-ion batteries (LiBs), widely used in handheld devices, electric cars, and grid storage systems, have become the linchpin of the energy storage industry. While X-ray imaging methodologies have gained significant traction over the last decade for their diagnostic potential in LiBs, they routinely struggle to provide insight into the chemical makeup within commercial batteries. Here, we performed the first in situ/ operando X-ray diffraction tomography study of a cylindrical Li-ion battery using a commercially available and industrially relevant 18650 NCA Li-ion battery.

Sample:

Commerical NCA cylindrical Li-ion battery

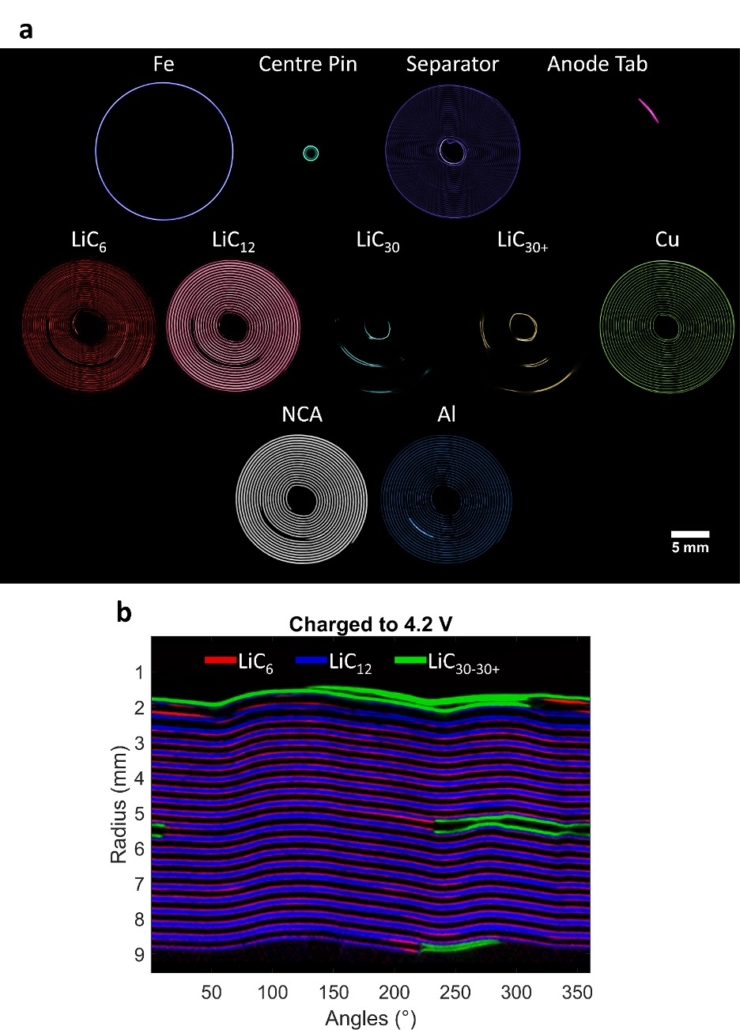

Figure. Spatial distribution of all components identified in the charged NCA battery cell. Panel a: First row presents the main cell components (Fe casing, centre pin, polymer separator, anode tab), the second row presents anode phases (LixC phases) and the anode current collector (Cu) and the third row presents cathode phase and the cathode current collector (Al). Panel b: virtually unrolled battery electrode charged to 4.2 V showing the distribution of LiC6, LiC30-30+ and LiC12,

Solution:

The study utilizes synchrotron X-ray diffraction computed tomography (XRD-CT) to investigate a commercial 18650 cylindrical LiNi0.8Co0.15Al0.5O2 (NCA) battery in operation and over seven cycles. Analysis of the spatially-resolved diffraction patterns revealed multiple chemical inconsistencies related to lithium distribution in both the cathode and anode. Notably, during battery charging, different activity levels concerning the lithiation process were observed in the anode. These included uniform lithiation, delayed lithiation, and a region inactive to lithiation. The latter was tied to specific cell geometry and remained constant across the cycling experiments. The delayed lithiation region directly affected nearby NCA properties during discharging, preventing full lithiation. Moreover, the aluminum tab had an adverse impact on the NCA it was in contact with, causing a different lattice parameter a and c evolution compared to the rest of the cathode.

Figure. Spatial distribution of anode LixC phases (LiC6, LiC12, LiC18, LiC30, LiC30+ and graphite) as the cell is charged to various potentials, starting from 2.65 V and ending to 4.2 V.

Benefits:

The study used the XRD-CT technique to analyze the evolving solid-state chemistry of a commercial cylindrical 18650 Li-ion battery under operating conditions, marking the first time this has been accomplished. Both the cathode and anode, as well as lithium distribution heterogeneities within each electrode and in the cell cross-section, were investigated using this high-resolution diffraction imaging method. Analysis of the vast, rich diffraction data was made possible through the state-of-the-art Parameter Quantification neural network (PQ-Net), leading to a detailed understanding of this multi-component system’s complex chemistry.

The research revealed three distinct regions in the anode that affected its interaction with lithium. The region inactive to lithiation primarily resulted from cell geometry, as it was close to the aluminum tab and separator where cathode material was lacking. The presence of a delayed-lithiation region at lower voltages could not be explained by cell geometry, but its effect was apparent as it negatively influenced lithium distribution at the cathode side. Despite the battery not being examined in situ during discharge, ex situ XRD-CT measurements indicated that the three identified regions behave similarly during cell discharging. This finding is key, as it suggests battery degradation could initiate in these regions, providing early identification of potential areas of cell degradation. Furthermore, the presence of the aluminum tab affected lithium distribution in the cathode material it was in contact with, impeding lithium insertion during discharging and trapping lithium during charging. This finding emphasized the impact of cell geometry on the initial capacity loss, driven primarily by anode side heterogeneities.

In conclusion, this study showcases the potential of XRD-CT in investigating battery degradation mechanisms. It can be applied to a variety of experiments, such as in situ/operando abuse testing to capture internal temperature gradients through the crystallographic behavior of the anode/cathode, and ex situ measurements to investigate active layer delamination and local corrosion of spent samples.

Further reading:

Emerging chemical heterogeneities in a commercial 18650 NCA Li-ion battery during early cycling revealed by synchrotron X-ray diffraction tomography. Matras, T.E. Ashton, H. Dong, M. Mirolo, I. Martens, J. Drnec, J.A. Darr, P.D. Quinn, S.D.M. Jacques, A.M. Beale, A. Vamvakeros, Journal of Power Sources, 231589, 2022, DOI: https://doi.org/10.1016/j.jpowsour.2022.231589

Read more about our team and further publications.