Case Study: Catalytic membrane reactor technology for sustainable ethylene production

Companies involved:

The University of Manchester, Berlin University of Technology, Eindhoven University of Technology, Memere, Ciaotech s.r.l., HyGear, Johnson Matthey, Finden Ltd, MARION TECHNOLOGIES, Quantis, Rauschert group, TECNALIA, VITO – The Flemish institute for technological research

Challenge:

Ethylene is a key building block of the chemical industry and is used in the production of many products including plastics. Over 150 million tonnes of ethylene are produced per annum, more than any other organic compound. Traditionally it is obtained by the highly energy intensive process of oil cracking in ‘naptha crackers’. The environmental lobby is exerting extreme pressure on these plants, calling for their closure. The search is on for new processes.

Solution:

We are developing technology using methane as a feedstock. This is highly desirable due to the dramatic increase in the availability of methane, driven by the continuous reduction of gas flaring and the exploitation of shale gas by hydraulic fracturing (fracking). Natural gas, whose main component is methane, is an abundant hydrocarbon source compared to crude oil and there is great interest in producing higher value bulk chemicals from it.

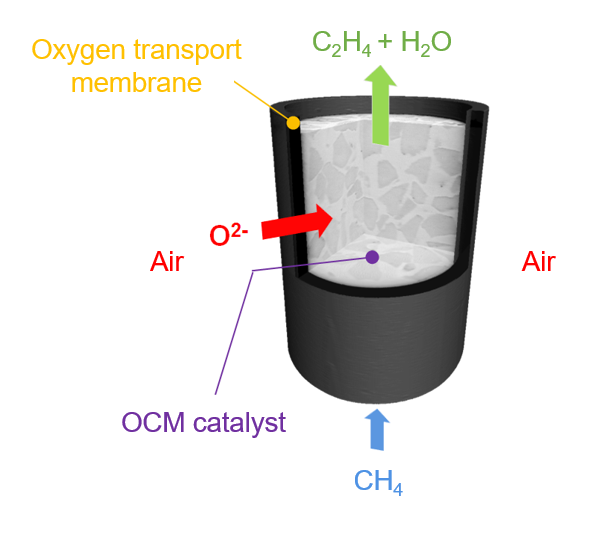

The oxidative coupling of methane (OCM) offers an economically viable route for ethylene production. Employing OCM with a new breed of reactor design produces dramatic cost reductions whilst providing an economically viable and environmentally friendly route for the production of ethylene. We use state-of-the-art catalytic membrane reactors, employing hollow fibre oxygen transport membranes. Under operation, oxygen from the air outside the reactor interacts with the membrane surface creating oxygen ions which are transported across the membrane. This delivers a source of pure oxygen to the reactor interior where it meets an incoming stream of methane. The catalyst inside the reactor facilitates the coupling of methane to yield ethylene product.

Benefits:

Finden works with leading companies and research institutions to demonstrate and scale-up this technology. We are are resolving chemical processes taking place within working reactor units and where problems such as deactivation occur, Finden finds solutions to overcome barriers to operation. Results in brief can be found at https://cordis.europa.eu/article/id/418475-novel-membranes-and-catalysts-reduce-greenhouse-gas-emissions-in-chemical-industry. More details about the project can be found on the Memere website.

You can also watch the videos: Introduction to the project ; Operando setup

Further reading:

In situ X-ray diffraction computed tomography studies examining the thermal and chemical stabilities of working Ba0.5Sr0.5Co0.8Fe0.2O3−δmembranes during oxidative coupling of methane. Dorota Matras, Antonis Vamvakeros, Simon D. M. Jacques, Vesna Middelkoop, Gavin Vaughan, Miren Agote Aran, Robert J. Cernik and Andrew M. Beale, Phys. Chem. Chem. Phys., June 2020, Advance Article, https://doi.org/10.1039/D0CP02144J

Real-time multi-length scale chemical tomography of fixed bed reactors during the oxidative coupling of methane reaction. Antonis Vamvakeros, Dorota Matras, Simon D.M. Jacques, Marco di Michiel, Stephen W.T. Price, Pierre Senecal, Miren Agote Aran, Vesna Middelkoop, Gavin B.G. Stenning, J. Frederick W. Mosselmans, Ilyas Z. Ismagilov & Andrew M. Beale. Journal of Catalysis, Volume 386, June 2020, Pages 39-52. DOI: https://doi.org/10.1016/j.jcat.2020.03.027

Real-time tomographic diffraction imaging of catalytic membrane reactors for the oxidative coupling of methane. Antonis Vamvakeros, Dorota Matras, Simon D.M. Jacques, Marcodi Michiele Vesna Middelkoopf Peixi Cong, Stephen W.T. Price, Craig L.Bull, Pierre Senecal, Andrew M.Beale, Catalysis Today, May 2020, https://doi.org/10.1016/j.cattod.2020.05.045

Effect of thermal treatment on the stability of Na-Mn-W/SiO2 Catalyst for the Oxidative Coupling of Methane. Dorota Matras, Antonis Vamvakeros, Simon Jacques, Nicolas Grosjean, Benjamin Rollins, Stephen Poulston, Gavin B G Stenning, Hamid Godini, Jakub Drnec, Robert J. Cernik and Andrew Michael Beale, Faraday Discuss., Jan 2020, Accepted Manuscript, https://doi.org/10.1039/C9FD00142E

Operando and Post-Reaction Diffraction Imaging of La-Sr/CaO Catalyst in the Oxidative Coupling of Methane Reaction. D. Matras, S. D. M. Jacques, S. Poulston, N. Grosjean, C. Estruch Bosch, B. Rollins, J. Paul Wright, M. Di Michiel, A. Vamvakeros, R. J. Cernik, and A. M. Beale. J. Phys. Chem. C, January 2, 2019 (web), 123, 1751–1760.

Real-Time Operando Diffraction Imaging of La-Sr/CaO During the Oxidative Coupling of Methane. Matras, D. Jacques, S. D. M. Godini, H. R. Khadivi, M. Drnec, J. Poulain, A. Cernik, R. J.Beale, A. M. J. Phys. Chem. C, 2018, 122, 2221-2230.

Real time chemical imaging of a working catalytic membrane reactor during oxidative coupling of methane A. Vamvakeros, S.D.M. Jacques, V. Middelkoop, M. Di Michiel, C.K. Egan, I.Z. Ismagilov, G.B.M. Vaughan, F. Gallucci, M. van Sint Annaland, P.R. Shearing, R.J. Cernik and A.M. Beale. Chem. Commun. (2015) 51, 12752

The research project receives funding from the European Community‘s Framework Programme for Research and Innovation Horizon 2020 (2014-2020) under grant agreement no. 679933.

Read more about our team and further publications.