Catalyst characterisation

Finden provides analytical insight for the development and improvement of catalysts. We use advanced characterisation to understand and reveal deactivation processes on and within intact catalysts. This can be catalyst bodies or structure such as extrudates and monoliths. Below you will find a case study and some published work which demonstrates our capabilities featuring mixture of static and in situ measurements.

Project highlights include:

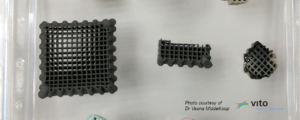

Fischer-Tropsch Synthesis: An alternative technology to produce vehicle fuel

The petrochemical industry produces vast quantities of hydrocarbons annually, and any improvement in catalytic efficiency can bring huge economic and environmental benefits. The Fischer-Tropsch Synthesis (FTS) process is likely to become increasingly important as an alternative technology for fuel production. It converts synthesis gas, a mixture of carbon monoxide and hydrogen, into useful hydrocarbons (like diesel or kerosene); one of the more viable and sustainable routes to replace gasoline or diesel fuel produced in oil refining and results in ultra-clean fuels. It is already used by a few petrochemical companies, but very few studies regarding the preparation and evolution of catalytically active species on a real ‘structured’ catalyst exist; this information is key for understanding the reasons behind variable catalyst performance.

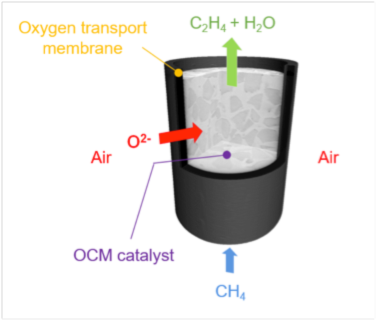

Catalytic membrane reactor technology for sustainable ethylene production

Catalytic membrane reactor technology for sustainable ethylene production

Ethylene is a key building block of the chemical industry and is used in the production of many products including plastics. Over 150 million tonnes of ethylene are produced per annum, more than any other organic compound. Traditionally it is obtained by the highly energy intensive process of oil cracking in ‘naptha crackers’. The environmental lobby is exerting extreme pressure on these plants, calling for their closure. The search is on for new processes. We are developing technology using methane as a feedstock.

Finden Ltd’s techniques for 3D imaging computed tomography recently appeared in the September 2017 edition of Chemistry World, in the article titled, “Diamonds are forever” which can be found at Chemistry World.

Webinar from Prof. Andrew Beale on studying catalytic materials with intense radiation sources

Our Chief Scientific Officer Prof. Andrew Beale gave a webinar for the UK Catalysis Hub discussing opportunities for studying catalytic materials with intense radiation sources;what, where, when and how.

It was in 1836 that Jöns Jacob Berzelius provided the first, basic description of a catalyst and its properties. Both the breadth and depth of our understanding of catalysts and catalytic processes has clearly progressed a lot since then – to a large extent this has been enabled by catalyst characterisation, performed increasingly in real time as the catalyst performs its function. Despite these developments, designing a catalyst/catalytic process from scratch is still incredibly difficult. Fortunately, characterisation methods, particularly those using bright light sources (i.e. X-rays, Lasers etc.) and ways in which catalysts & catalytic process can be interrogated are constantly evolving. In this webinar Prof. Andrew Beale discussed some recent exciting studies performed by his group and others and explained how the wider catalysis community can engage with and benefit from such developments. He concluded with an overview of some of the planned technical developments on the horizon and suggested where there might be future possibilities for researchers on the quest to unravel the secrets behind what makes a catalyst work?

The webinar featured a presentation from Prof. Andrew Beale of 40 minutes, followed by a Q & A session. Watch a recording of the webinar below.

Read more about our team and publications.